Description

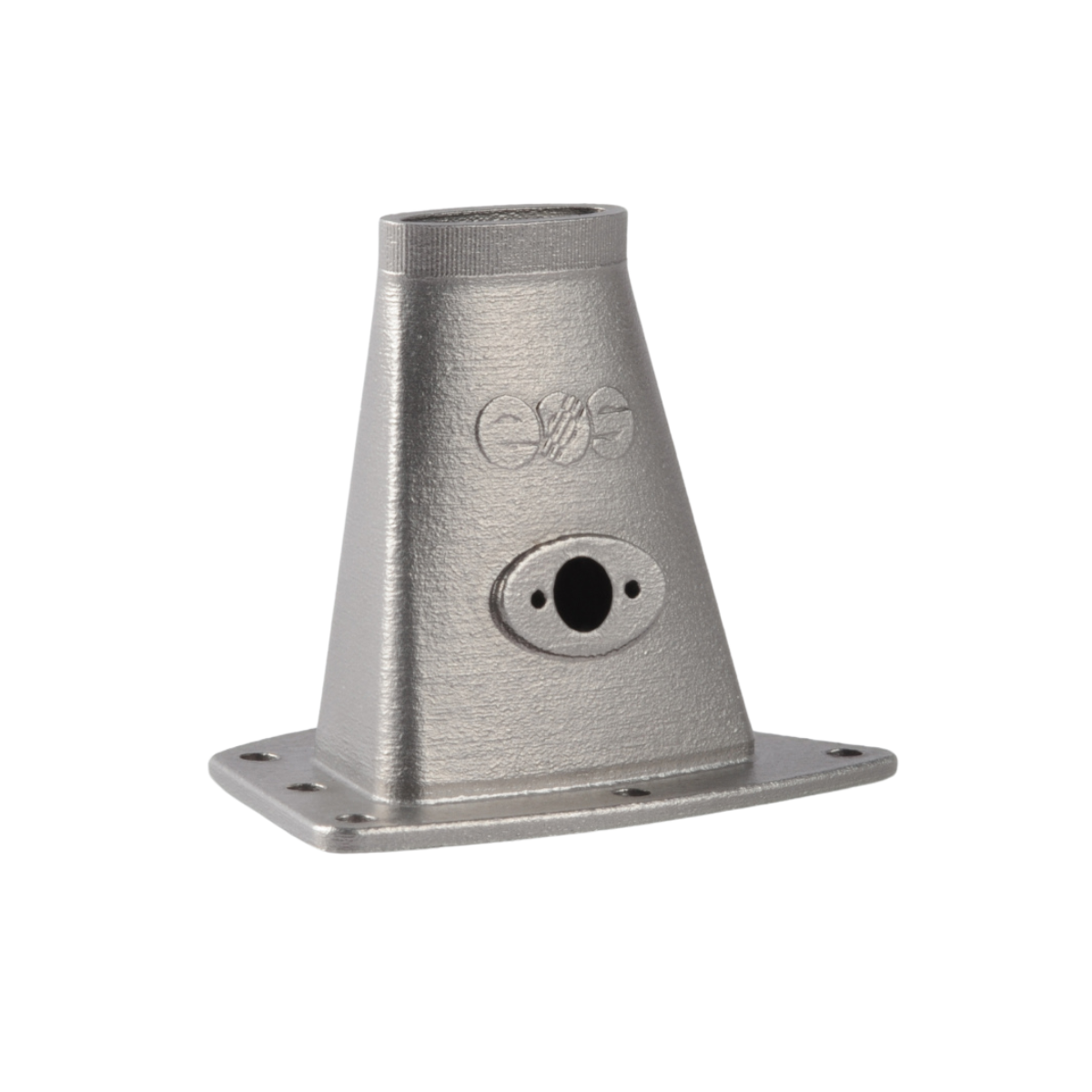

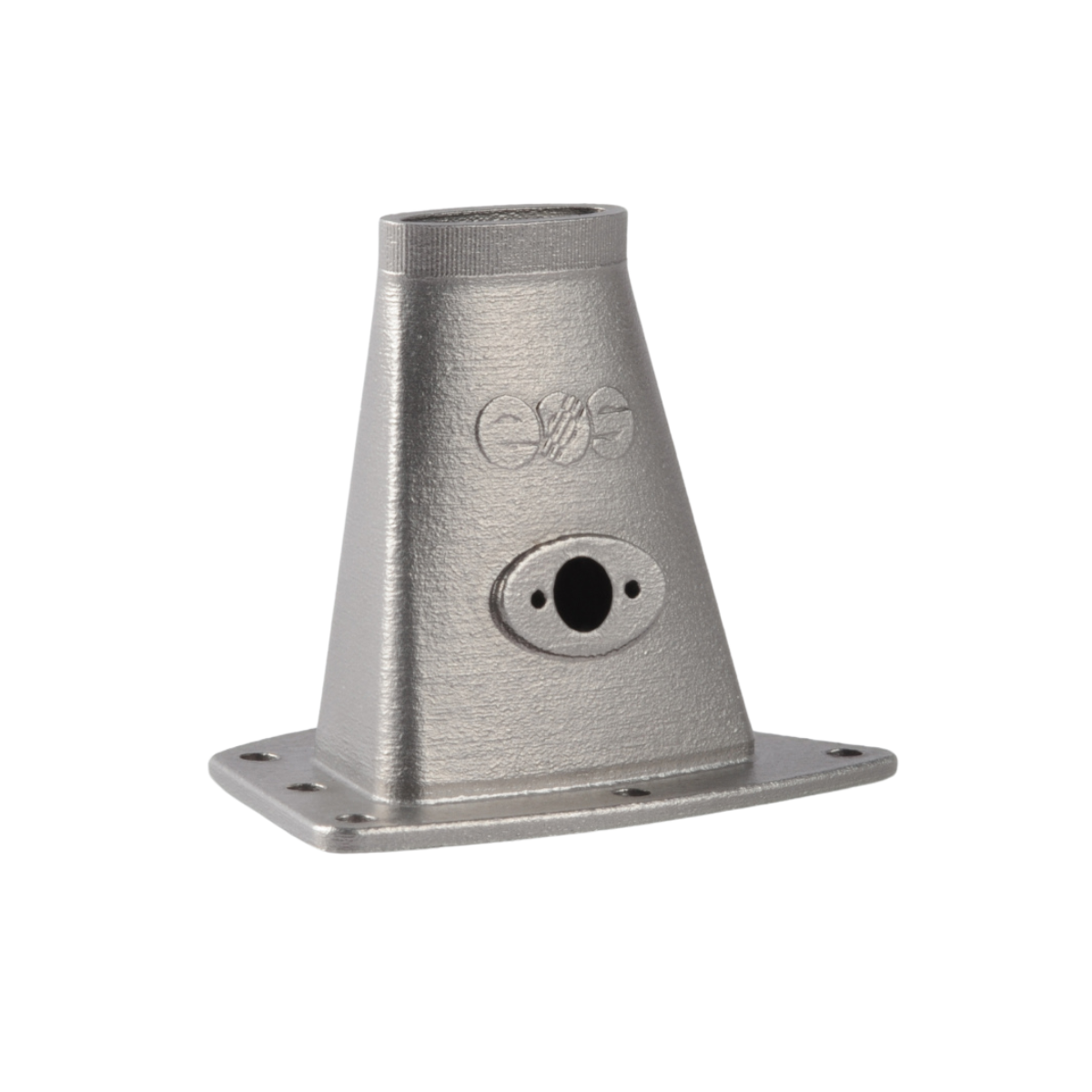

EOS NickelAlloy HX is a high-strength, oxidation-resistant nickel-chromium-iron-molybdenum alloy, effective up to 1200°C. Ideal for aerospace and gas turbine parts, it offers excellent properties in both as-built and solution heat treated states. Solution annealing of the laser sintered material will homogenize the microstructure, relax internal stresses and increase the elongation, while slightly decreasing the strength. Standard laser processing parameters results in full melting of the entire geometry, typically with 40 μm layer thickness. Parts built from EOS NickelAlloy HX can be heat treated and material properties can be varied within specified range, resulting in parts that can be heat treated, machined, welded, polished, and coated if required. Unexposed powder can be reused.

Learn more about EOS Metal Solutions

Safety Data Sheets SDS on myEOS (no login required)