EOSTATE Exposure OT & Smart Fusion for Metal Additive Manufacturing

Description

Realize your full potential with our Certificate Program for EOSTATE Exposure OT and Smart Fusion for metal laser powder bed fusion process (L-PBF). Dive into an immersive learning experience specifically designed for application engineers, process engineers and quality assurance engineers.

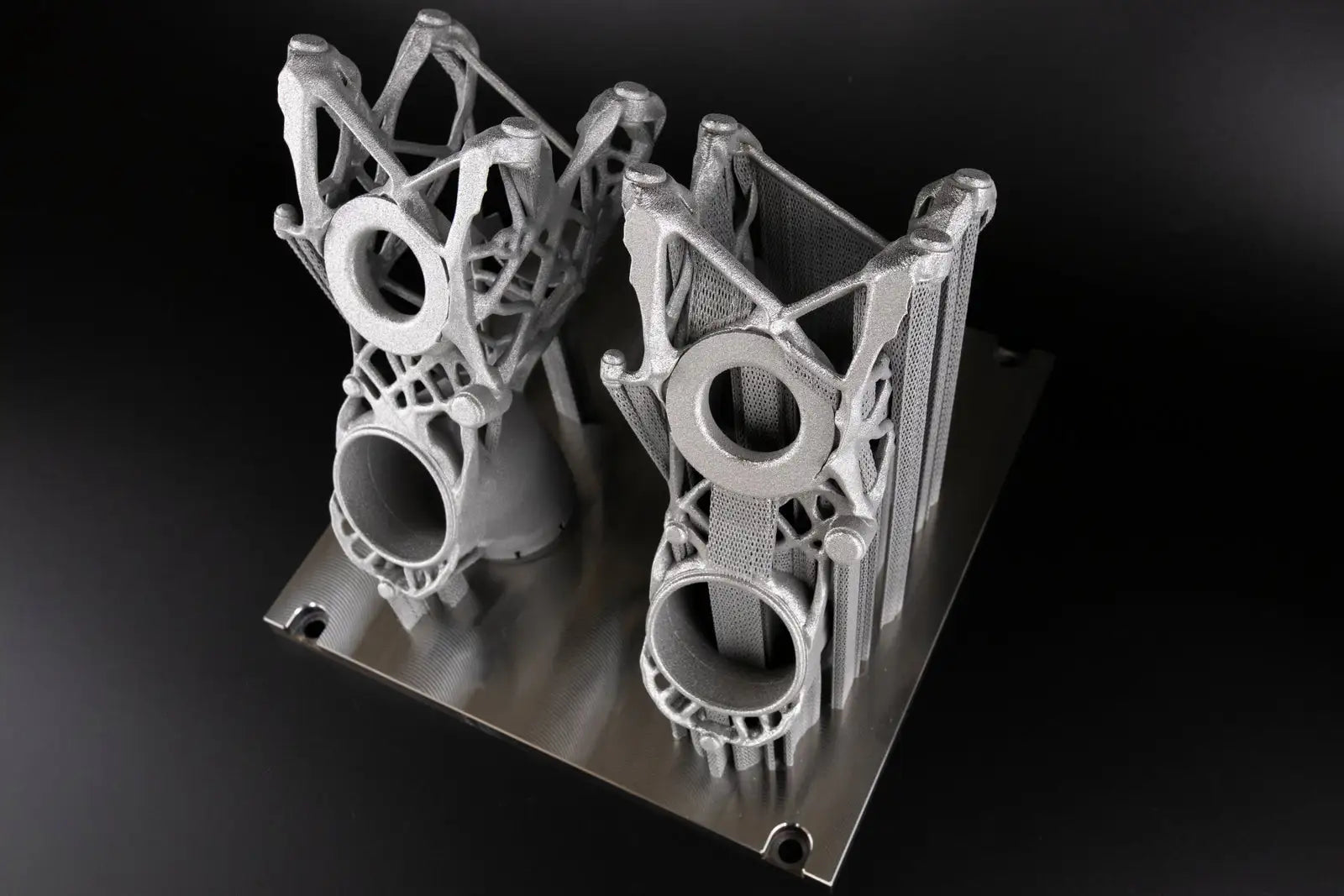

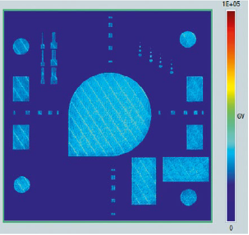

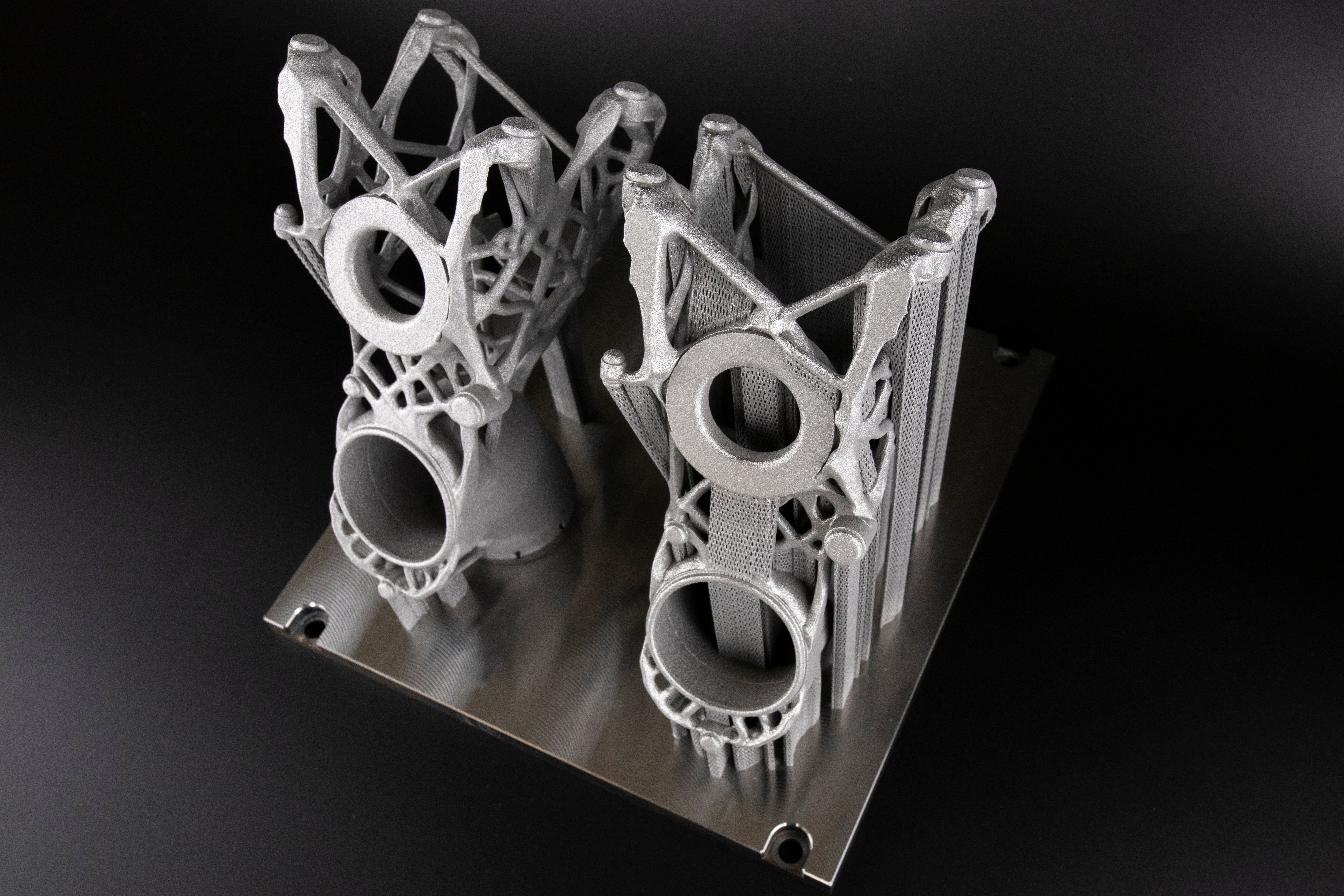

In additive manufacturing, every aspect of the process chain matters. In this brand-new certificate program, we focus on monitoring and optimization of L-PBF process with EOSTATE Exposure OT, which is a unique solution in the AM market that can monitor the process behavior not only during melting, but also after solidification. This enables the engineers to control the process in a closed feedback loop manner with Smart Fusion.

Our AM certificate program will teach you how to implement process monitoring best practices to deepen your process understanding and document production not only for quality assurance, but also for support-free AM with Smart Fusion, which utilizes OT data to regulate the process live.

Set to launch in June 2024, this program represents a unique opportunity to advance your skills in AM. Secure your spot today and be among the first to benefit from this innovative learning experience.

Program Benefits

-

Gain a thorough understanding of the L-PBF process monitoring.

Gain a thorough understanding of the L-PBF process monitoring. -

Upskill yourself to utilize data driven Support-free AM.

Upskill yourself to utilize data driven Support-free AM. -

Apply theoretical knowledge through hands-on tasks.

Apply theoretical knowledge through hands-on tasks. -

Build a robust network within the additive manufacturing (AM) expert community.

Build a robust network within the additive manufacturing (AM) expert community. -

Access continually updated content for staying at the forefront of industry advancements.

Access continually updated content for staying at the forefront of industry advancements. -

Benefit from safer, faster, and more stable build jobs moving forward.

Benefit from safer, faster, and more stable build jobs moving forward. -

Engage directly with EOS engineers during insightful expert sessions.

Engage directly with EOS engineers during insightful expert sessions. -

Obtain a recognized certificate from the industry leader in AM.

Obtain a recognized certificate from the industry leader in AM.

Learning Objectives

Upon completing this certificate program, participants will be able to:

-

Describe the basic principles of OT

Describe the basic principles of OT -

Describe the basic principles of Smart Fusion:

Describe the basic principles of Smart Fusion: - How it works

- How it enables support-free building and thermal management

-

Execute nominal OT signal intensity determination method (Target Grey Value)

Execute nominal OT signal intensity determination method (Target Grey Value) -

Plan and perform validation methodology for testing mechanical properties

Plan and perform validation methodology for testing mechanical properties -

Apply application-specific design & process guidelines

Apply application-specific design & process guidelines -

Create a roadmap to develop own applications

Create a roadmap to develop own applications

Course Overview

Your training is split into five phases:

- Introduction to the Program: Brief welcome and overview of the Process Science and Engineering Polymer Certificate Program.

- Program Objectives: High-level discussion on what students will learn throughout the program, including key skills and knowledge areas.

- Module 1 - Physical Fundamentals: Explore the mechanisms of light emission during L-PBF and image generation paths

- Module 2 - Software: Learn how to use the OT software and its benefits by focusing on the monitoring data workflow

- Module 3 - Use Cases: Master the settings on specific machines and get inspired by the monitoring implementation use cases.

- Module 1 - Basics: Explore the Smart Fusion technology and check its add values such as heat input management, Support free building, less material use (sustainability), shorter development cycle.

- Module 2 - Theory: Learn why supports are not only not needed, but also should ideally be avoided; Master energy input management in L-PBF and how Smart Fusion regulates the process heat automatically. Experience how to activate and set Smart Fusion parameters in EOSPRINT. Gain deep knowledge on OT Signal intensity (Grey Value) behavior and calculate process target GV for Smart Fusion. Get insights on selection of exposure strategy.

- Module 3 - Qualification: Learn about the EOS Quality Triangle and critical to quality approach for qualification. Explore the different phases in qualification. Explore the methodology that is being used by EOS for Smart Fusion qualification and create your own qualification strategy.

- Module 4 - Case Studies: Follow different case studies step by step to gain solid understanding of the learnings from the previous modules and start to think about your roadmap for using Smart Fusion to push the limits of AM.

- Customer Benefit: Learn in detail the benefits of OT monitoring, such as shortening of quality assurance cycles loops, process optimization and documentation of AM. Understand different image types and their significance.

- Advance Features: Master the automatic anomaly detection feature, how to set up the detectors, analyze the findings and creating reports.

- OT Maintenance: Navigate the OT Software and learn how to perform and verify calibrations.

- Case Study: Learn through practical case studies that demonstrate how to apply OT monitoring data to setup Smart Fusion Parameters.

- Final Assessments: Evaluate your learnings with tailored review questions.

- Expert Session: Conclude your EOSPRINT 2 training with an expert session during which you can bring up your questions, open points, and exchange with EOS experts for your specific application. You will be then ready to apply your new skills to achieve remarkable results in your additive manufacturing projects.

What Our Students Say

FAQ

Real World Experience

Explore and assess real-world projects with case studies and portfolio examples.

Community & Experts

Receive valuable feedback from tutors and other learners in peer reviews, Q&A sessions and discussion groups.

Hands On Practice

Gain vital experience in methodologies and processes while working on practical tasks, exercises, and tools.

Flexible Learning

Learn at your own pace and access modules on the go with our self-study online classes.

Find Out More

Want to learn more about this certificate program or other courses? Get in touch with our AM Academy experts to schedule a call today.

Book a free consultation