| EOS M-System | EOS M 400 | EOS M 400 | |

| Materials | EOS NickelAlloy IN718 | EOS Titanium Ti64 | |

| Layer Thickness (µm) | 40 | 30 | |

| Tensile as-manufactured Samples | Vertical | 42 | 69 |

| Horizontal | 42 | 69 | |

| Tensile Heat Treated Samples | Vertical | 42 | 42 |

| Horizontal | 42 | 41 | |

| Sum of Tensile Samples | 168 | 221 | |

| Tensile Sample Positions | 9/9 | 9/9 | |

| Defect Analysis Samples | 20 | 5 | |

| Defect Analysis Sample Positions | 5/9 | 5/9 | |

Description

- Analyze the capability of the AM solution (system, powder, and process combination) to produce consistent part properties and save time by not having to build all the test components from scratch.

- Use the mechanical raw data of the data package to create optimal design for components produced with AM technology.

- Choose the optimal material, process and system combination for your application by comparing the performance of different materials and processes across EOS M system types.

- Speed up the qualification of your part production process on a given system-process-material combination.

- Speed up initial AM technology performance evaluation, to smoothen the decision to enter AM.

- Tensile data with orientation and location information across the build platform

- Defect analyses with spatial information across the build platform

- 150 – 450 data points in total, depending on material-system- process combination. The higher the Technology readiness level (TRL) is, the more there is data.

View the table below to know the available dataset for different material-system- process combination.

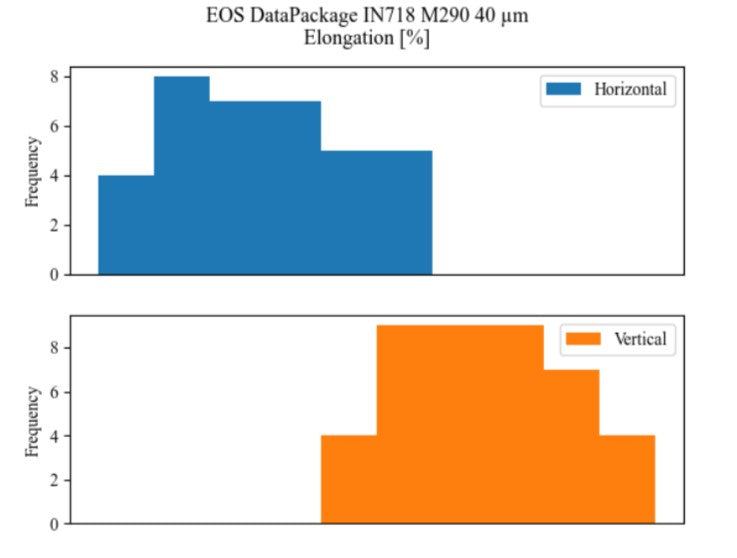

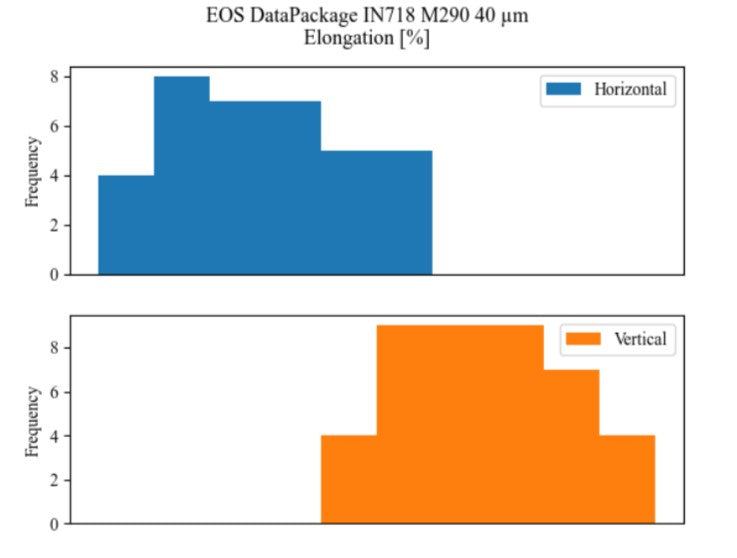

| EOS M-System | EOS M 290 | EOS M 290 | EOS M 290 | EOS M 290 | |

| Materials | EOS Alumium AlSi10Mg | EOS Nickel-Alloy IN718 | EOS ToolSteel 1.2709 | EOS Titanium TiCP | |

| Layer Thickness (µm) | 30 | 40 | 40 | 30 | |

| Tensile as-manufactured Samples | Vertical | 123 | 41 | 42 | 21 |

| Horizontal | 96 | 36 | 36 | 18 | |

| Tensile Heat Treated Samples | Vertical | 42 | 42 | 188 | 21 |

| Horizontal | 36 | 36 | 162 | 18 | |

| Sum of Tensile Samples | 297 | 155 | 428 | 78 | |

| Tensile Sample Positions | 8/9 | 8/9 | 8/9 | 8/9 | |

| Defect Analysis Samples | 20 | 20 | 55 | 90 | |

| Defect Analysis Sample Positions | 5/9 | 5/9 | 5/9 | 5/9 | |

| EOS M-System | EOS M 290 | EOS M 290 | EOS M 290 | |

| Materials | EOS Titanium Ti64 | EOS Titanium Ti64 Grade5 | EOS Titanium Ti64 Grade23 | |

| Layer Thickness (µm) | 60 | 40 | 40 | |

| Tensile as-manufactured Samples | Vertical | 63 | 42 | 42 |

| Horizontal | 54 | 36 | 36 | |

| Tensile Heat Treated Samples | Vertical | 63 | 84 | 84 |

| Horizontal | 54 | 72 | 72 | |

| Sum of Tensile Samples | 234 | 234 | 234 | |

| Tensile Sample Positions | 8/9 | 8/9 | 8/9 | |

| Defect Analysis Samples | 20 | 30 | 30 | |

| Defect Analysis Sample Positions | 5/9 | 5/9 | 5/9 | |

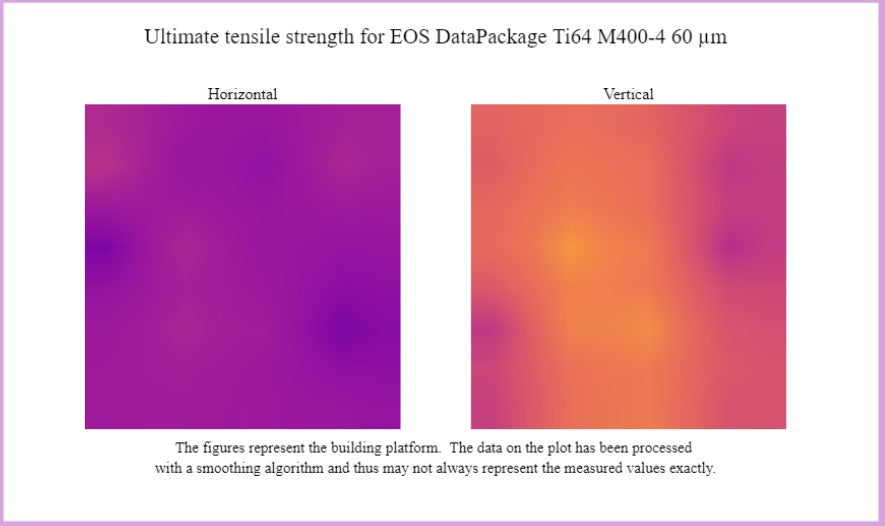

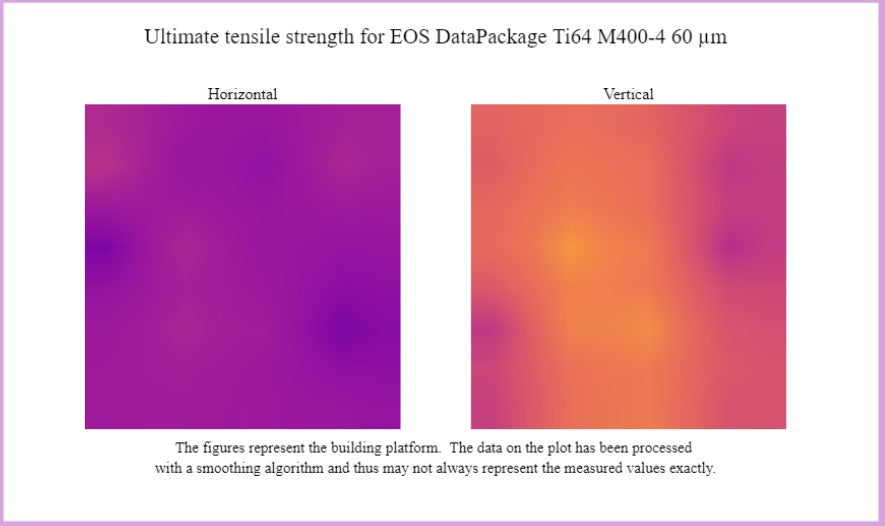

| EOS M-System | EOS M 400-4 | EOS M 400-4 | EOS M 400-4 | EOS M 400-4 | |

| Metal Materials | EOS Alumium AlSi10Mg | EOS Nickel-Alloy IN718 | EOS Titanium Ti64 | EOS Titanium TiCP | |

| Layer Thickness (µm) | 40 | 40 | 60 | 30 | |

| Tensile as-manufactured Samples | Vertical | 94 | 0 | 0 | 0 |

| Horizontal | 73 | 0 | 0 | 0 | |

| Tensile Heat Treated Samples | Vertical | 14 | 120 | 120 | 119 |

| Horizontal | 14 | 95 | 96 | 95 | |

| Sum of Tensile Samples | 195 | 215 | 216 | 214 | |

| Tensile Sample Positions | 9/9 | 16/16 | 16/16 | 16/16 | |

| Defect Analysis Samples | 19 | 0 | 40 | 40 | |

| Defect Analysis Sample Positions | 5/9 | 0/9 | 16/16 | 16/16 | |

By purchasing the Data Package the users acquire information about measurements results obtained by the interaction of EOS system, EOS powder and EOS process for their exclusive and unrestricted use.

The content of this Data Package is provided for information purposes only and EOS makes no representation or warranty, and disclaims any liability, with respect to the measurement results achieved. Measurement results are dependent on a variety of influencing factors and therefore, actual results achieved by the user may deviate from the information stated in the Data Package.

This document does not on its own represent a sufficient basis for any part design, neither does it provide any agreement or guarantee about the specific properties of EOS Systems, system settings, a material or part or the suitability of a material or a part for a specific application.

The achievement of certain part properties as well as the assessment of the suitability of this material for a specific purpose is the sole responsibility of the user.

Furthermore, the user is prohibited from disclosing information from this Data Package to third parties and refrain from any form of publication. In the event of unauthorized disclosure, EOS reserves the right to take legal action against the user.