Description

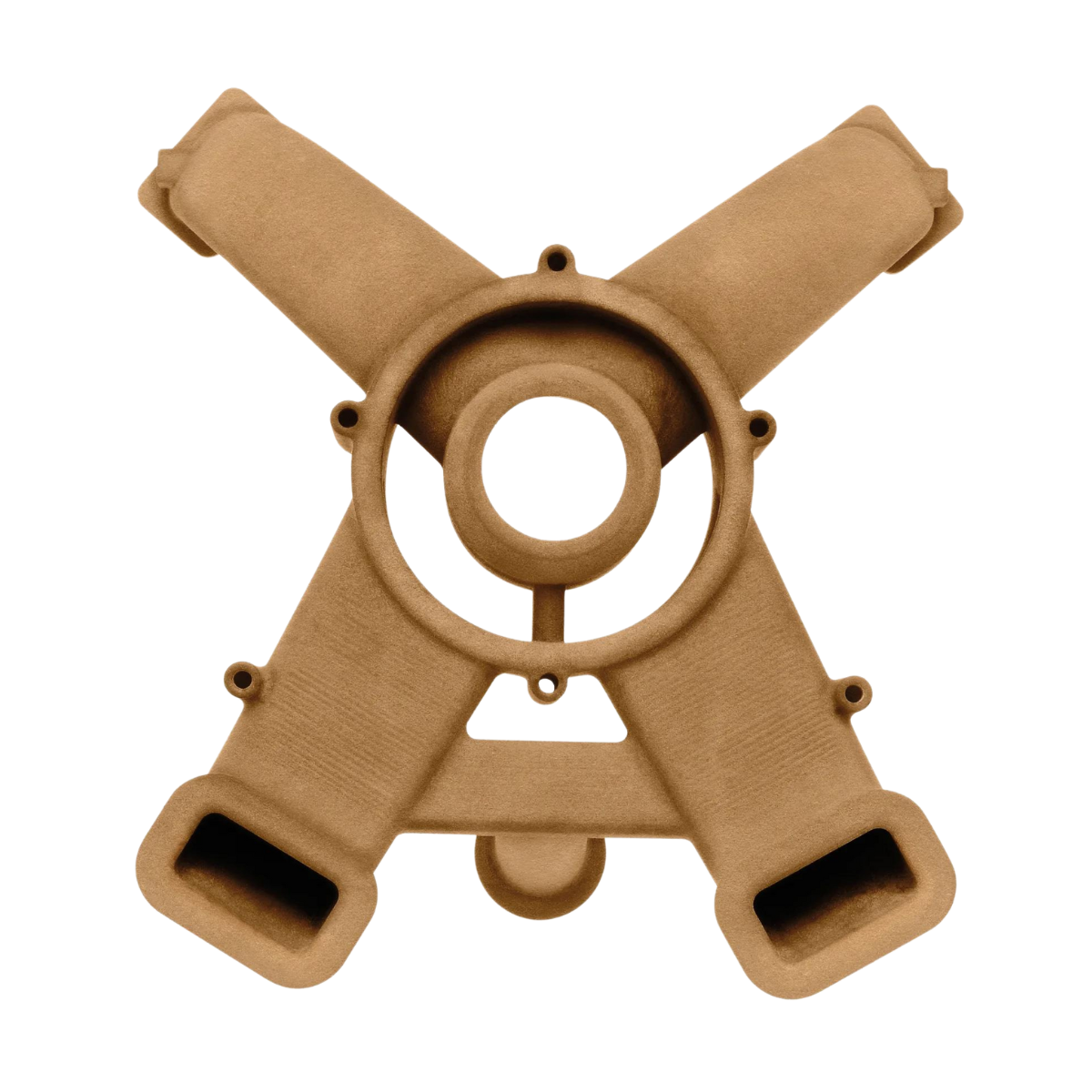

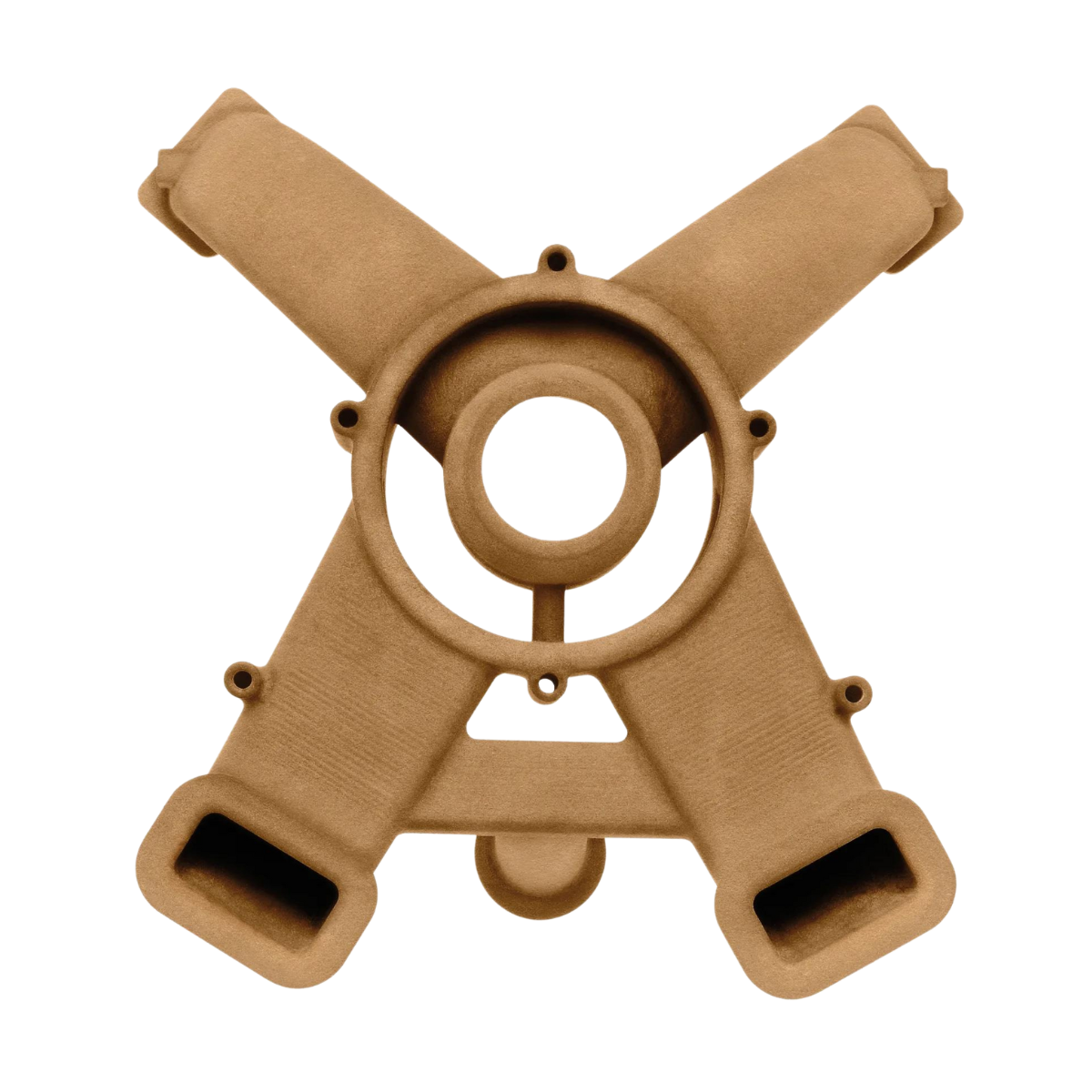

This high-performance polymer is based on an unfilled PEKK and shows higher elongation at break and impact strength while maintaining high tensile strength compared to the carbon fiber-filled material HT-23.

At high operating temperatures in the range of 80-180°C, this material demonstrates its unique capabilities and shows a massive increase in toughness while maintaining high strength and stiffness. The color of PEKK 100 is beige.

Learn more about EOS Polymer Solutions and ALM Custom Material Solutions

*The image shown presents air duct system for use in aviation (Source: EOS | Royal)

The data corresponds to our knowledge and experience at the time of publication. They do not on their own represent a sufficient basis for any design, neither do they provide any agreement about or guarantee the specific properties of a product or part or the suitability of a product or part for a specific application. It is the responsibility of the producer or customer of a part to check its properties as well as its suitability for a particular purpose. This also applies regarding the consideration of possible intellectual property rights as well as laws and regulations. The data are subject to change without notice as part of EOS' continuous development and improvement processes.