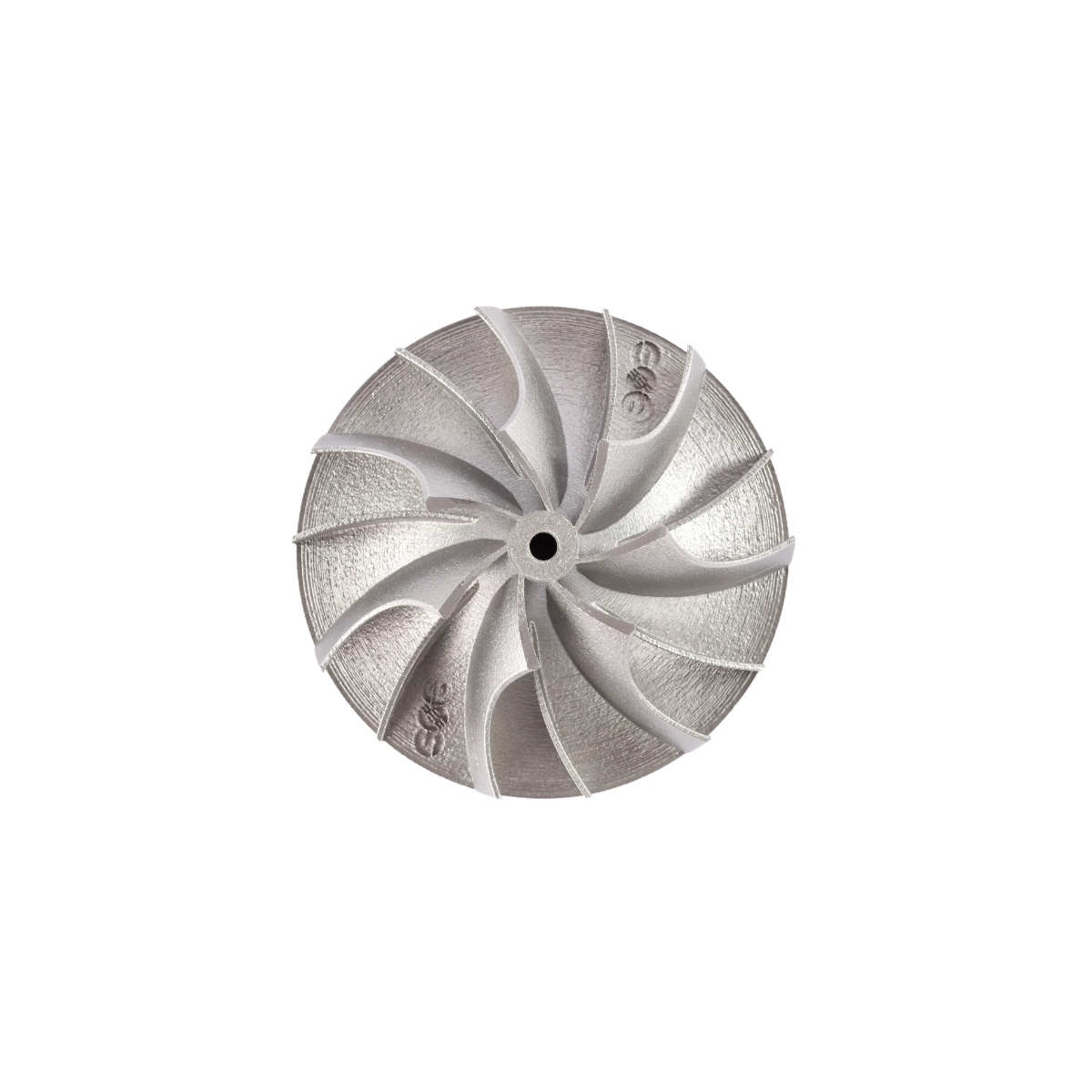

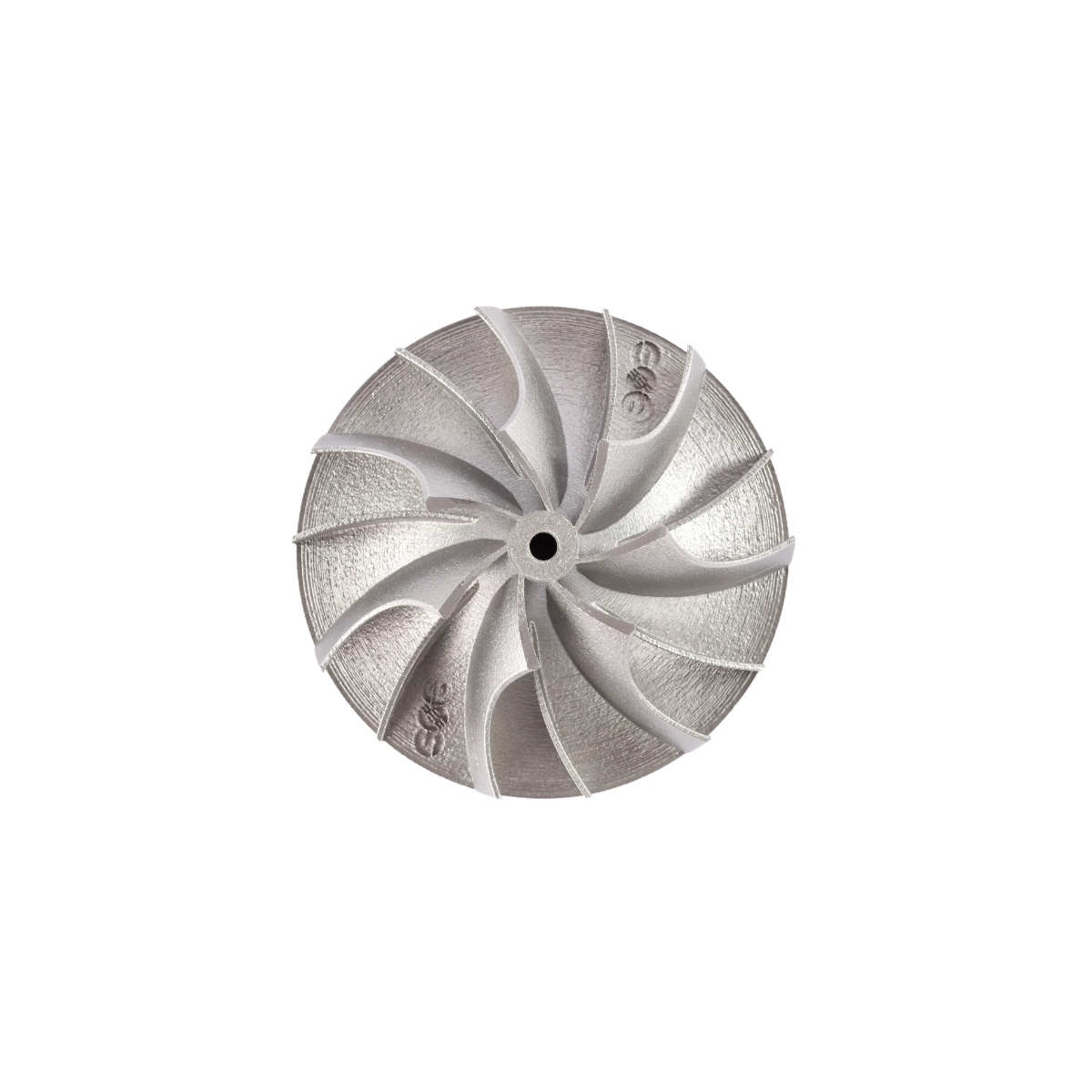

Description

Parts built from EOS NickelAlloy IN625 are characterized by having high tensile, creep and rupture strength. Conventionally cast or wrought components in this type of nickel alloy have typically excellent fatigue and thermal-fatigue properties combined with good oxidation resistance. EOS NickelAlloy IN625 is expected to have good corrosion resistance in various corrosive environments. Especially sea-water applications require high pitting and crevice corrosion resistance, stress-corrosion resistance against chloride ions, high tensile and corrosion-fatigue strength.

Parts built from EOS NickelAlloy IN625 can be heat treated and material properties can be varied within specified range. Parts can be machined, spark-eroded, welded, micro shot-peened, polished and coated in both as-built and in heat-treated conditions. Due to the layerwise building method, the parts have certain anisotropy.

Learn more about EOS Metal Solutions

Safety Data Sheets SDS on myEOS (no login required)