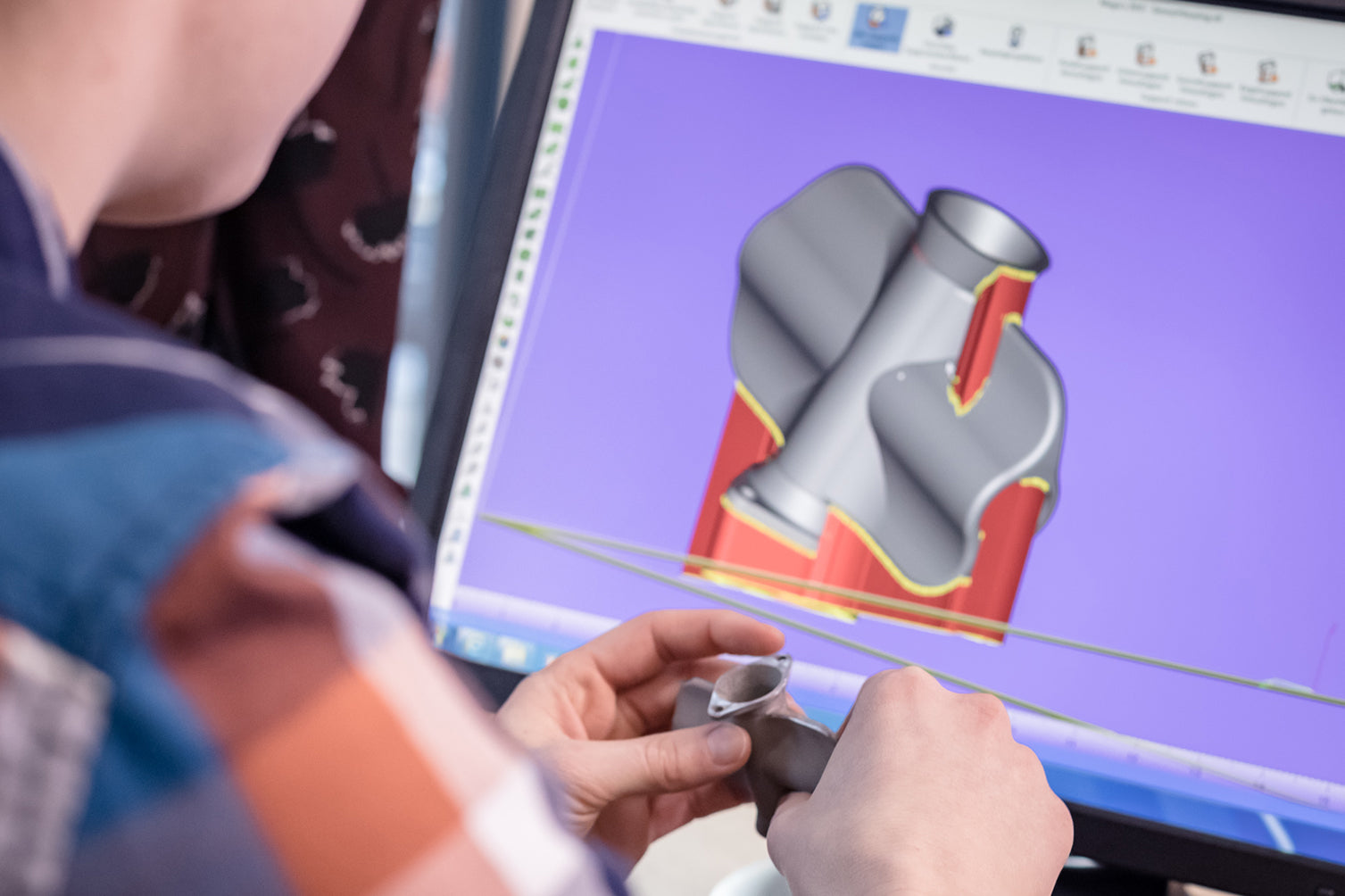

Entdecken Sie, was die Additive Minds Academy von EOS zu bieten hat

Interesse an AM-Training, aber Sie sind sich nicht sicher, wo Sie anfangen sollen?

Unsere Vorab-Beurteilungen helfen Ihnen, den besten Weg zu wählen, damit Sie sich mit dem geeigneten Lernpfad auseinandersetzen. Dies passt auch perfekt zu Ihrem Onboarding-Prozess, um sicherzustellen, dass jedes Teammitglied in kürzester Zeit das benötigte Wissen erwirbt.

Buchen Sie eine kostenlose Bewertung